Why Us

Learn what sets us apart from our competition!

Who We Are

With 21+ years of industry related experience and 70 completed Ninja projects last year, we have become the world leader in Ninja course design and construction. Our company has completed projects in the United States, Canada, Ethiopia, Australia, Germany, Russia, United Arab Emirates, Sweden and more.

We provide end-to-end solutions—design, in-house fabrication, project management, installation, training, and more—so all the pieces of your project are coherent and cared for. Through our engineering excellence and passion for quality, innovation and safety, we produce designs that are stunning, safe, and strong through years of heavy use.

OUR EXPERIENCE

Ninja Solutions was the first company to offer commercial course designs to the recreational market, and as a result we now know what works. Not content to rest on our laurels, we continue developing, engineering, and testing to provide the best quality components.

Beyond our Ninja expertise, we also operate within the realms of rock climbing, ziplines, aerial parks, and parkour. This broader competence with all things adventure allows us to support your current and future business needs.

Being based in the US, we understand the ever-changing state and federal regulations that may impact your business. Though these regulations often vary geographically, we offer certified engineering plans and stamps for every state in the US. We strive to provide exceptional experiences, both on-stage and behind-the-scenes.

HIGH QUALITY

We are always striving to find the highest quality materials offering maximum safety and minimum maintenance. Whether indoors or out, rest assured that your adventure assets will withstand thousands of users pounding and playing for years.

Take, for example, the cable rope in many of our activities. It is stronger and more durable then standard rope (rated to 14,000 lbs!), with swaged fittings to ensure the course is safe and professional.

Another example is the rubberized grips we use on our monkey bars – they provide awesome grip and comfort. We tested scores of options before finding one cushy enough for comfort and hard enough to last. Similarly, our warped walls are built using laminated plywood with a rubberized running surface.

Other top quality materials that we use include solid aluminum plates on our traverse box, alloyed aluminum truss frames, high-test rope, powder coated steel, carbon fiber, acrylic, and stainless steel.

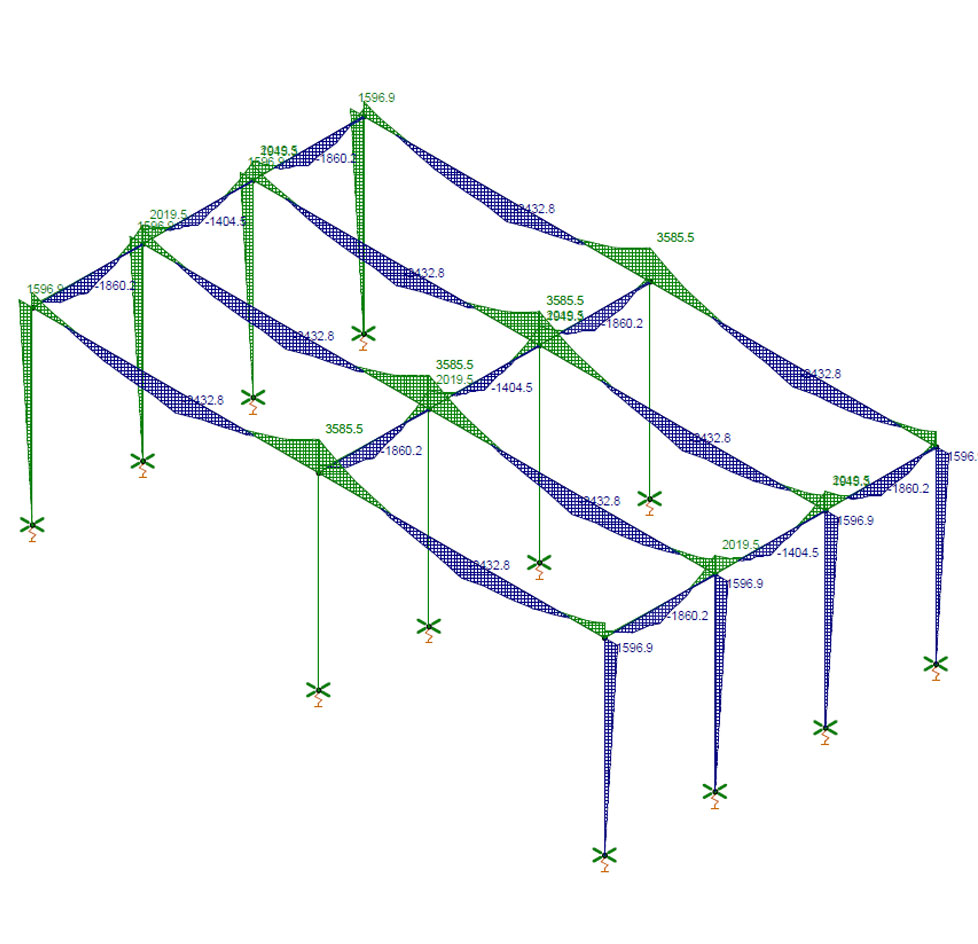

DESIGN PHASE

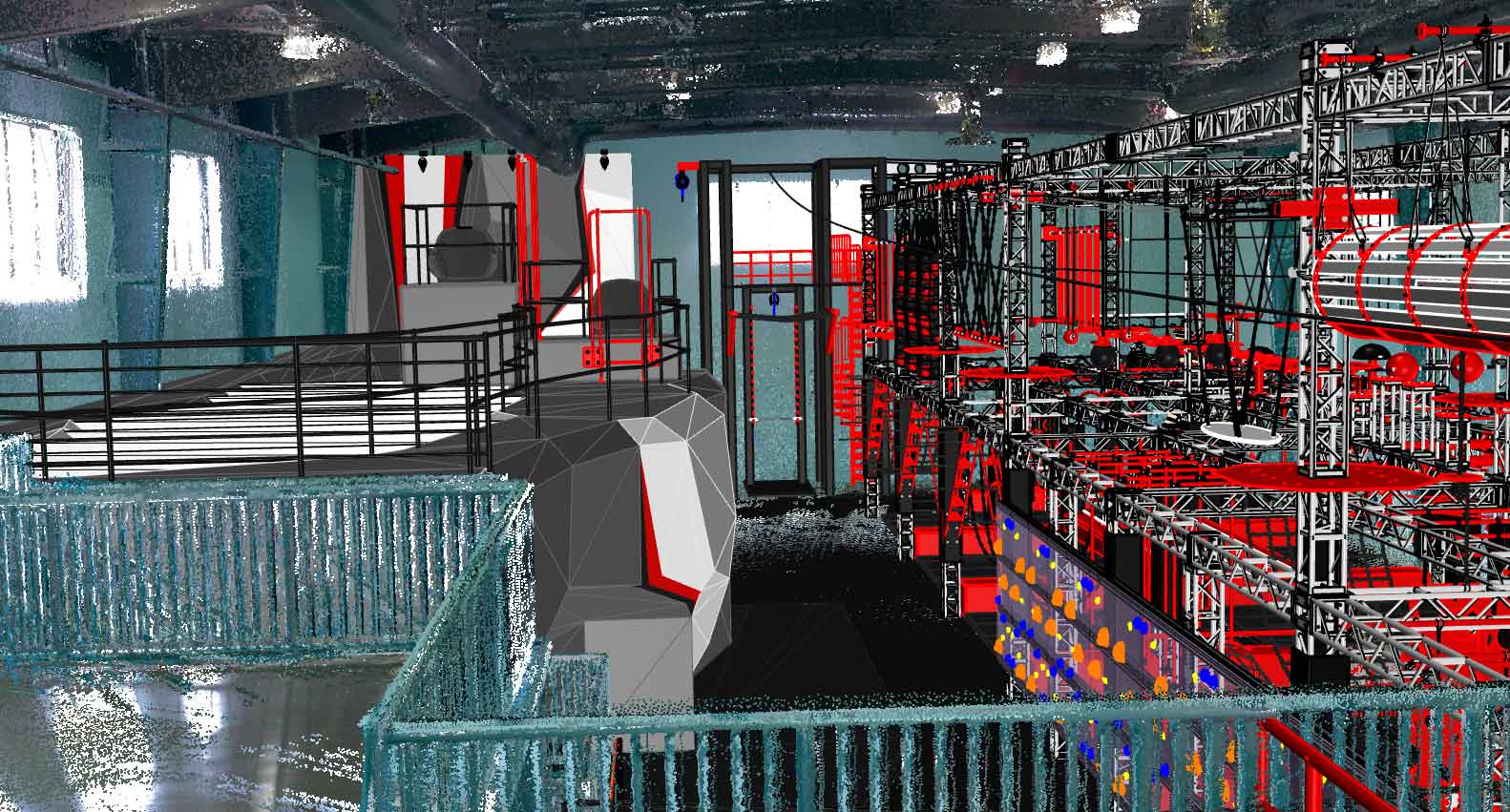

We begin by discussing your goals, budget, and vision. Centrally, who is the course for? What level of thrill is ideal? Given these baseline inputs, we evaluate your site, assessing the physical layout and conditions to see if they match your vision. From there, we develop a course layout and design for the overall project, communicating along the way via 3D digital designs. We also offer 3D building scanning. This allows us to overlay your project within the building. By doing this it allows us to look for issues where the equipment and building conflict. Once you have reviewed and accepted the proposal, the project officially begins.

INNOVATION

We are constantly innovating, exploring new materials and experiences. We stay abreast of innovations in play, applying insights from dozens of sports into the realm of Ninja Solutions. Each and every one of our products are made in the USA, fabricated in-house by our employees.

With over 100 elements to choose from, we offer more customizability than any other company! Take for instance, our constantly evolving timer systems. Our latest system includes age group brackets and records over time, tailored to the desires of a data-driven generation. Other unique options we offer include fogger systems, airbags (for indoors or outdoors), glow in the dark (or other incorporated lighting), a plethora of colors, and much more.

ADAPTABILITY

All of our obstacles and courses are designed with adjustability and scalability in mind. Any component can be interchanged with another from our vast selection, and individual elements can be tuned per age or skill level. No matter the size of your space (whether micro or grand) we can design a course to meet your needs. We offer a variety of course layouts for standard, elevated, or multi-story Ninja structures.

We also use aluminum trusses known not only for their strength but flexibility. More attachment options—both overhead and under platforms—allow for easy adjustment and swapping out of each element.

Another example of adjustability can be found in our use of micro-slings, enabling quick changes to many of our hanging elements. Narrowing or widening the distance between hanging cones takes mere seconds. Raising or lowering the height of the trapeze bars is a snap.

Our traverse box is another great example of in-built extensibility – each solid aluminum plates with over 90 connection holes. This matrix of holes allows for minute or major adjustments. Spread things out to increase the difficulty or for change out the element completely (e.g. swapping pegs, for floating stairs, spinning doorknobs, or any number of other options).

SAFETY

For us, safety is not an afterthought, but rather an integral part of our entire process. With the extreme nature of this sport, mitigating risk is crucial to your customers and your business. While all our padding meets ASTM fall height ratings, we consider the whole experience. Whether users are flailing or flawless, we ensure that safeguards match the movements.

We design our courses with a three foot padded safety border on the sides, six foot safety areas at the start and finish, and highlighted trip edges at key points. We provide padding for truss columns, railings, and gaps (with soft barrier nets). Many of our competitors do not offer these options.

We also use carbon fiber bars on the salmon ladder, flying bar, and pipe slider obstacles. While extremely strong and durable, it weighs just three ounces, so if and when it hits a person, the impact is negligible.

MANUFACTURE AND INSTALLATION

Once our designers and fabricators create your custom course, we ship them from our U.S. facilities to your location. To install your course, we can either provide a full team, or one head builder to work alongside your own labor force. We can work around your schedule, with installs typically taking one to three weeks.

Once installed, we will train your staff on use and maintenance, answering any and all questions you may have. Obviously, safety is fundamental, and ours continues from the initial design and construction through to actual customer participation. In addition, because of the inherent exposure faced by adventure industry companies, Ninja Solutions carries a $2 million general liability insurance policy that covers products and completed operations for all of our clients No other company can match our extreme commitment to our clients!

PROJECT MANAGEMENT

We believe a properly planned project leads to better outcomes. To this end, we combine our proven project management methodology with an affirmative attitude to ensure all projects come in on time and on budget. Our project managers meet with the client team and other stakeholders each week to ensure that milestones are being met and team members are well-informed and connected. This process ensures enhanced communication, improved risk management, and better efficiency and effectiveness of services. We are proud of our process, and are not aware of any other industry competitor that manages its projects this way.

WANT TO GET STARTED?

WE’D LOVE TO HEAR FROM YOU!